Noda Technologies

Noda Technologies

Turning aluminium smelting into a flexible energy asset — safely and intelligently.

We develop advanced sensing and control that reveals the real-time state of the Hall-Héroult electrolyte, enabling predictive control and safe demand flexibility in one of the world’s most energy-intensive processes.

Why it matters

Hydropower provides stability today, but interconnections and new large loads (AI datacentres, semiconductors) are tightening long-term capacity margins. Flexibility and predictability are becoming strategic assets. Observability is the foundation: safe change begins with knowing the cell’s true state.

Our technology

Our maintenance-free anodic current-sensor platform synchronously samples current distribution in the HH cell, providing a direct proxy for the electrolyte’s kinetic and thermodynamic state—data not captured by voltage-only monitoring. This unlocks predictive control, safer process adjustments, better component lifetime, and prepares smelters for controlled flexibility.

- Process observability Continuous insight into cell behavior; fewer hazardous manual diagnostics.

- Predictability & safety Maintain bath parameters (liquidus temperature, alumina concentration, side ledge integrity) while adjusting current.

- Grid readiness Prepare for flexibility mechanisms and evolving market/policy signals.

- Path to pilots Short paid PoC (2–3 months) to co-create the business case; 2026 pilot (TRL 5) with non-dilutive funding.

Context & insights

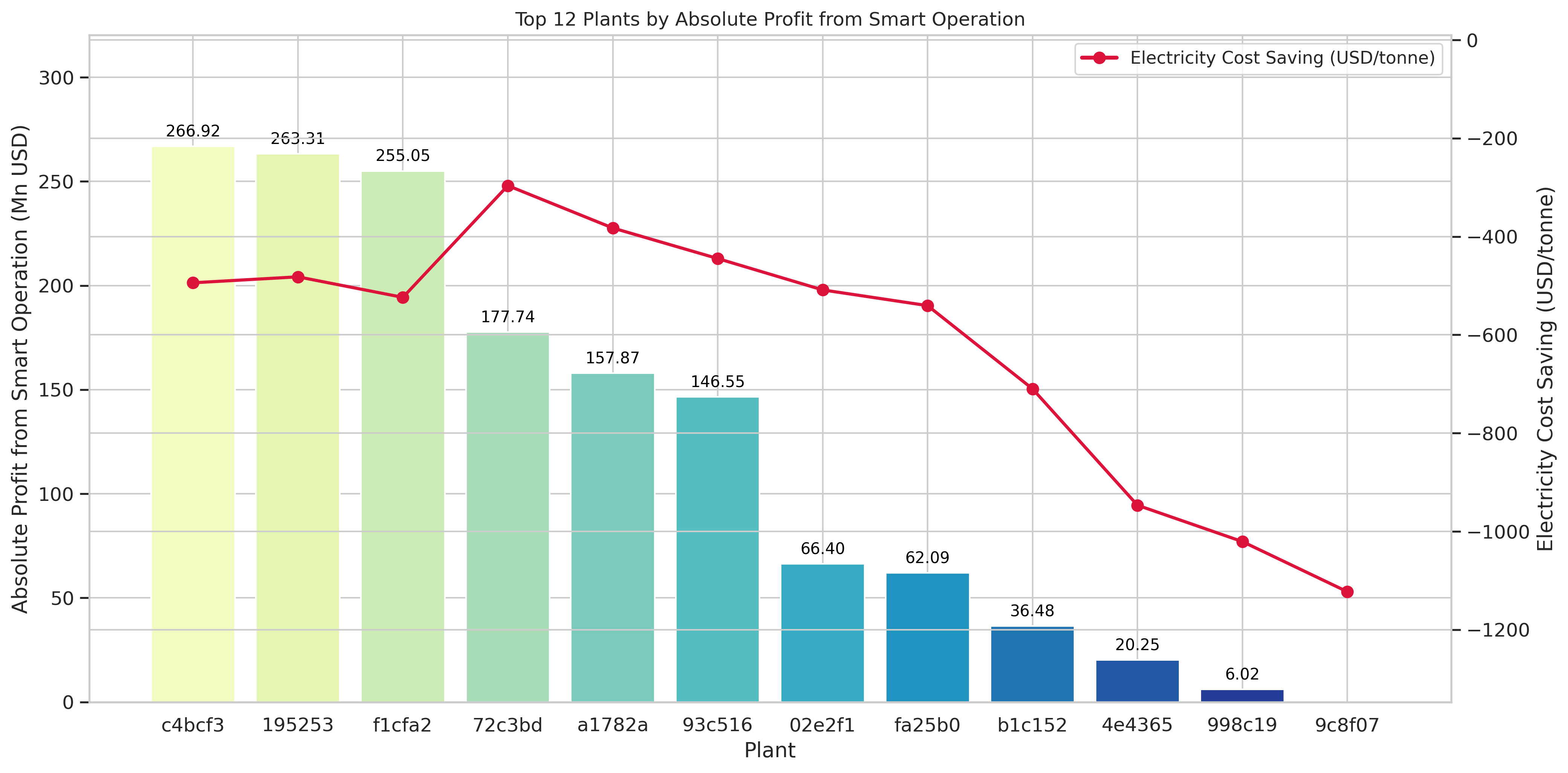

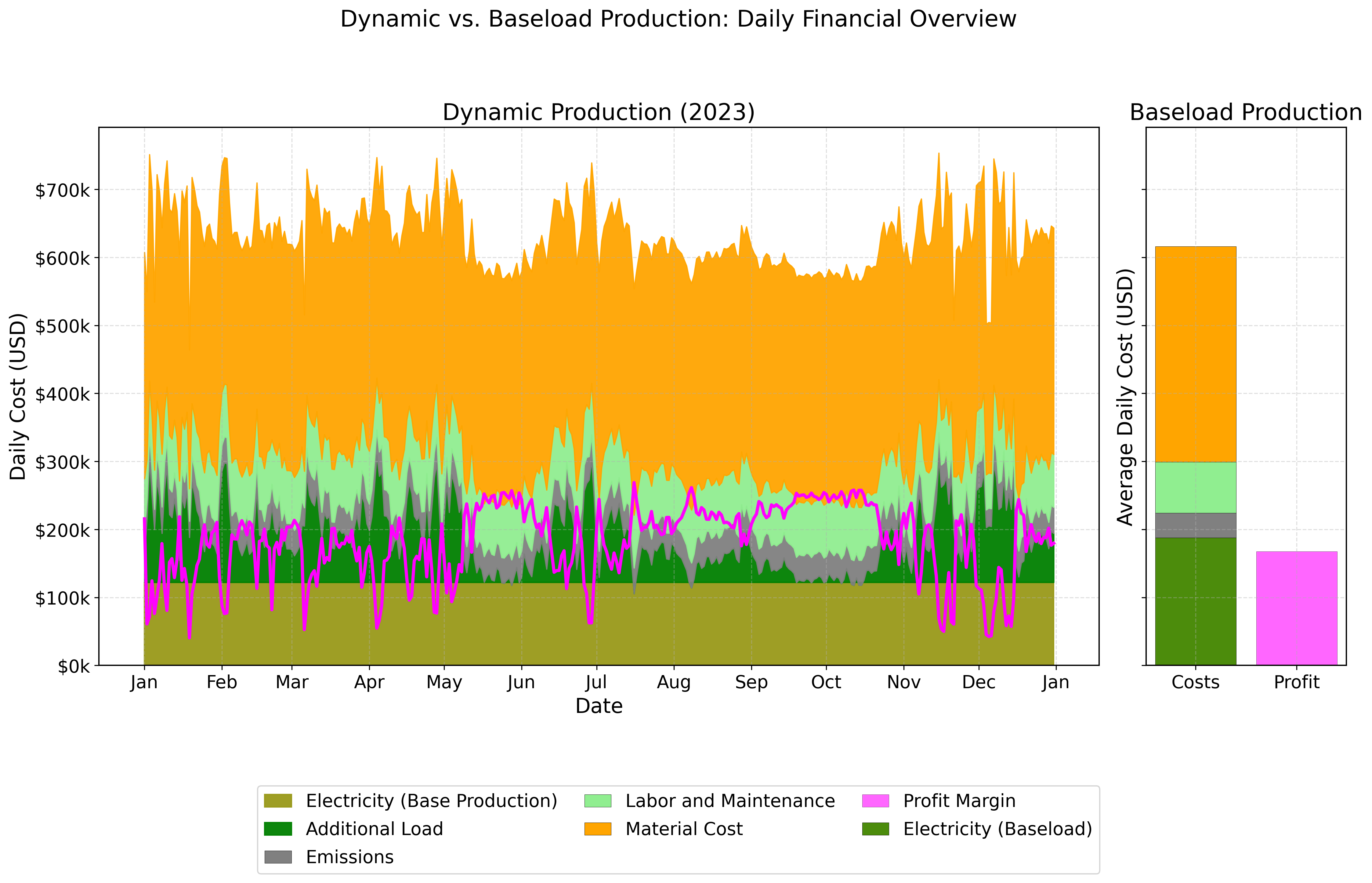

European market data (2021–2024) show that Nordic smelters achieved strong profit and cost gains under flexible operation—conditions comparable to Québec’s hydropower context.

Recognition

- ICSOBA 2025 — paper accepted on market-driven optimisation of aluminium smelting operations.

- Sweden–Canada InnoMatch 2025 — selected participant (RISE/Vinnova).

Collaboration & contact

We’re preparing short, paid PoC collaborations (2–3 months) with aluminium producers and grid stakeholders to co-create the value and ROI model for flexible smelting, followed by a 2026 pilot (TRL 5). We’re open to establishing a local presence in Canada as collaborations mature.

Contact us: founders@noda.technology